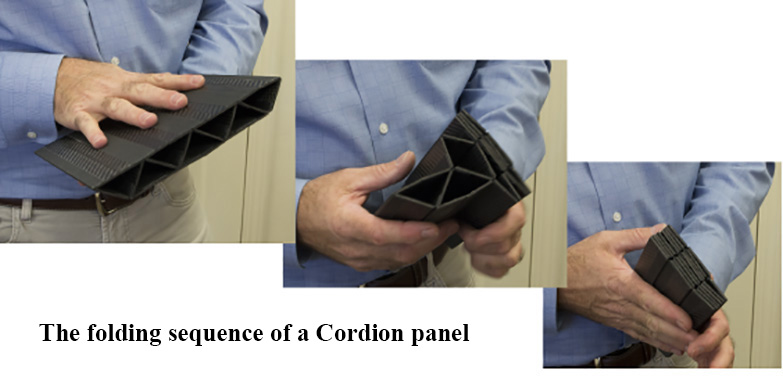

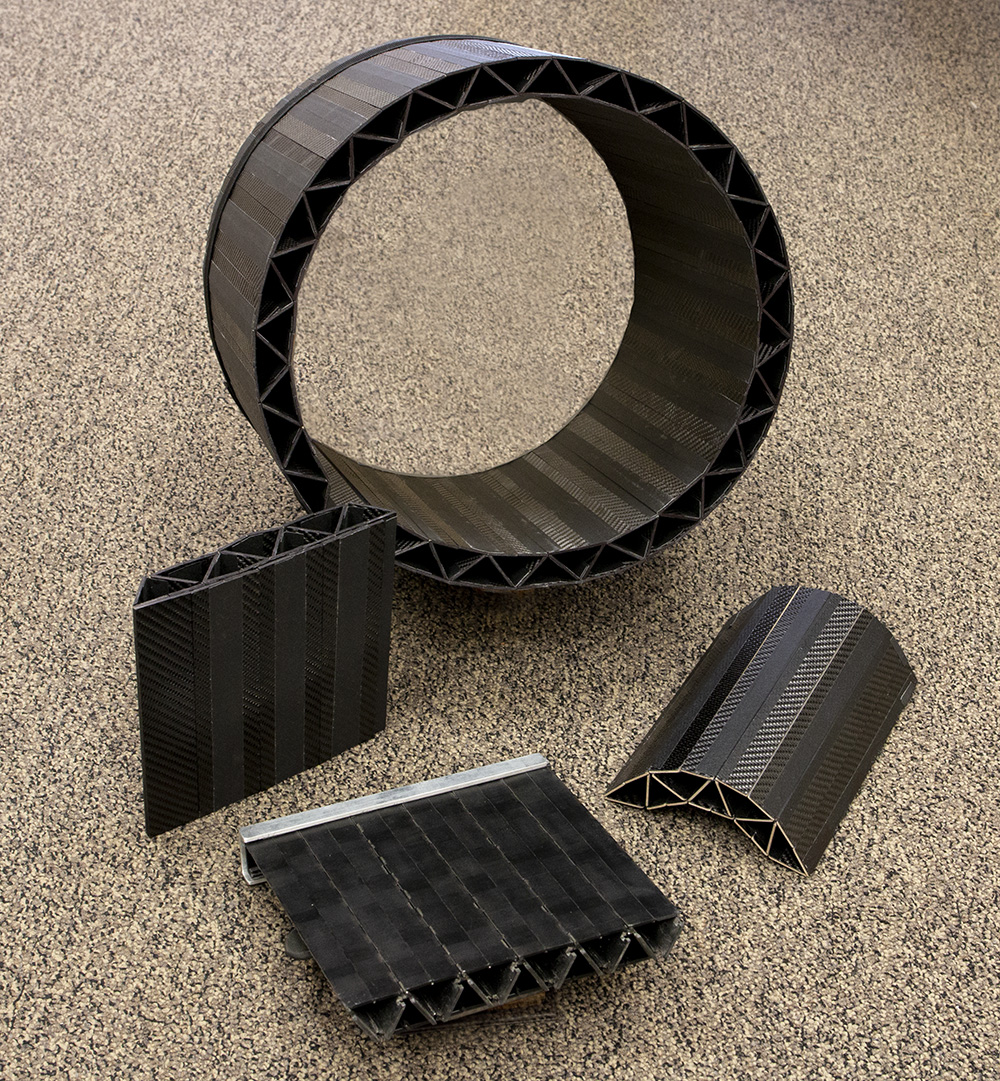

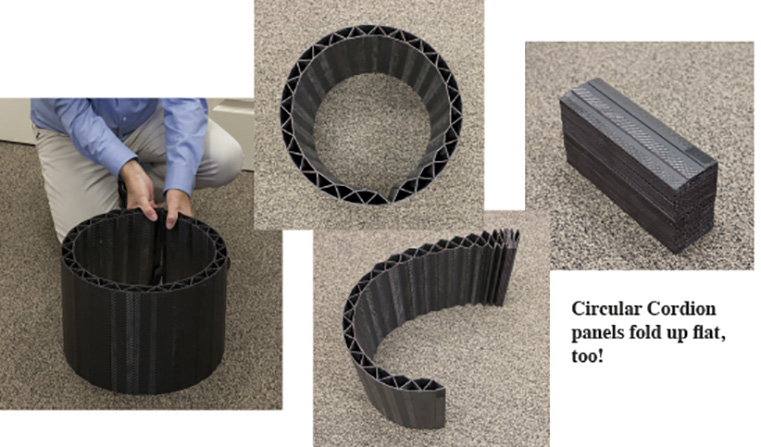

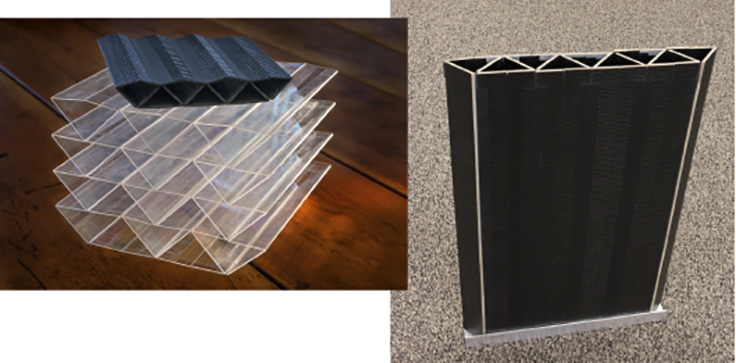

The fundamental basis of Cordion technology is a folding geometry which forms an expandable panel. Cordion panels can create a wide variety of products such as folding boats for rescue, commercial, and recreational applications, folding antennas and other types of sensors for military and first-responder agencies, agricultural equipment, bridges, temporary shelters, landing pads, flooring, ballistic protection panels, and much more. Cordion can be made from metal, composite, wood, plastic—a vast range of materials and combinations to meet differing design requirements. Because Cordion is at its heart a truss system, it can be very strong and lightweight, yet still fold up to be more compact than a solid panel would be. Cordion products can be designed to balance both strength and space-saving properties.

Cordion panels can be flat, curved, or a combination of both. They can fold in a straight line, or radially like a fan. Cordion panels can be supported on their edges, they can be supported internally, they can be held in tension by cables, and they can be designed to self-extend.